- Home Page

- Company Profile

-

Services

- Instrumental Analysis

- Preparative HPLC

- Total Organic Carbon Instrumental

- Gas Chromatography - GC

- X-ray Photoelectron Spectroscopy- XPS

- TESTING LAB

- Liquid Chromatography -HPLC

- GCMS

- LCMS

- Particle Size Analysis by Sedigraph

- Gel Permeation Chromatography - GPC

- Ion Chromatography

- Thermogravimetric Analysis - TGA

- Differential Scanning Colorimetry - DSC

- UV Visible Spectroscopy - UV-Vis

- Fourier Transform Infrared Spectroscopy - FTIR

- Inductive Couple Plasma Spectroscopy - ICP

- Atomic Absorption Spectrophotometry - AAS

- Energy Dispersive X Ray Fluorescence Spectroscopy

- Nuclear Magnetic Resonance Spectroscopy - NMR

- Colour Measurement Macbeth Spectrophotometer

- Particle Size Analysis by Malvern Mastersizer

- Scanning Electron Microscopy - SEM

- SEM-EDAX

- Transmission Electron Microscopy - TEM

- X Ray Diffraction - XRD

- Surface Area & Pore Volume Analysis by BET

- Porosity Measurement Mercury Porosimeter

- Surface Tension by Surface Tensiometer

- Elemental Analysis Using Elemental Analyzer - CHNS

- CHEMICAL TESTING LAB

- Microbiological Analysis

- Atomic Force Microscopy - AFM

- Particle Size Testing by Sympatec

- MALDI-MS

- ZETA POTENTIAL BY ZETA SIZER

- PARTICLE SIZE ANALYSIS BY NANOSIZER

- Product Analysis

- Pigment Analysis

- Perfume Flavours Fragrance Essential Oil Analysis

- Environmental - Water Analysis

- Metal & Metal Alloy Analysis

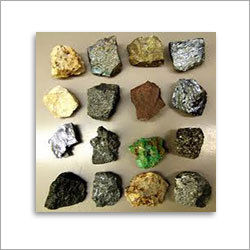

- Mineral Ores Analysis

- Plastic Polymer Analysis

- Fertilizer Soil Analysis

- Coal Analysis

- Thermic Fluid Waste Oil Analysis

- Petroleum Products Fuel Analysis

- Vegetable Oil & Fats Analysis

- Textile Analysis

- Soaps Detergent Analysis

- Food Analysis

- Electric Components Analysis

- Cementious Material & Fly Ash Analysis

- Analytical Testing Laboratories

- Speciality Chemicals Services

- Instrumental Testing

- GPC Testing

- GC Testing

- LCMS Testing

- GCMS Testing

- HPLC Testing

- Ion Chromatography Testing

- TGA Testing

- DSC Testing

- UV Testing

- FTIR Testing

- ICP Testing

- AAS Testing

- XRF Testing

- NMR Testing

- Colour Measurement Testing

- Particle Size Testing by Malvern Mastersizer

- SEM Testing

- SEM-EDAX Testing

- TEM Testing

- XRD Testing

- Surface Area & Pore Volume Testing

- Porosity Measurement Testing

- Surface Tension Testing

- CHNS Testing

- TOC Testing

- Testing Laboratory

- MICROBIOLOGICAL TESTING

- XPS Testing

- AFM Testing

- Particle Size Testing

- MALDI-MS Testing

- ZETA POTENTIAL TESTING BY ZETA SIZER

- Particle Size Testing by Nanosizer

- Particle Size Testing by Sedigraph

- Preparative HPLC Testing

- Product Testing

- Pigment Testing Services

- Perfume-Fragrance-Essent Oil Testing Services

- Nitrosamines Impurities Testing by LCMS

- Water Testing Services

- Metal Testing Services

- Ores Testing Services

- Polymer Testing Services

- Fertilizer Soil Testing Services

- Coal Testing Services

- Thermic Fluid Testing Services

- Petroleum Testing Services

- Vegetable Oil Testing Services

- Textile Testing Services

- Detergent Testing Services

- Food Testing Services

- Electric Components Testing Services

- Fly Ash Testing Services

- Chemicals Testing Services

- Solvent Testing Services

- Chemical Testing Services

- Lab Testing Services

- Laboratory Testing Services

- Instrumental Analysis

- Contact Us

Plastic Polymer Analysis

Product Details:

- Frequency 50 Hz

- Interface Digital

- Measuring Range Wide range suitable for various polymer types

- Temperature Room temperature to 200C

- Voltage 220 V

- Display Digital LCD Display

- Size Customizable

- Click to view more

X

Plastic Polymer Analysis Price And Quantity

- 1 Unit

- Windows OS

- Automatic and manual options

- Overload protection, auto shut-off

- Minimum 10 mg

- Up to 20 samples/day

- Digital report

- High precision, ±0.1%

- FTIR Spectroscopy, Differential Scanning Calorimetry (DSC)

Plastic Polymer Analysis Product Specifications

- Customizable

- Room temperature to 200C

- Digital LCD Display

- 220 V

- Digital

- 50 Hz

- Wide range suitable for various polymer types

- 350 W

- Electric

- Variable as per sample

- Plastic Polymer

- Identification and characterization of polymers, material quality testing, research and development

- Windows OS

- Automatic and manual options

- Overload protection, auto shut-off

- Minimum 10 mg

- Up to 20 samples/day

- Digital report

- High precision, ±0.1%

- FTIR Spectroscopy, Differential Scanning Calorimetry (DSC)

Plastic Polymer Analysis Trade Information

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1000 Unit Per Month

- 4-10 Days

- Australia, Middle East, Africa, Central America, Eastern Europe, South America, Western Europe, Asia, North America

- All India

Product Description

We provide qualitative services for Plastic & Polymer Analysis to our highly reputed clients. It is used for testing plastic as per the requirements of diverse clients. We have our unit equipped with progressive technology and machinery which is used or rendering our services smoothly and efficiently. Plastic & Polymer Analysis stands high on quality, durability, effectiveness and reliability. This has lead to highly increasing demands of our services in the market. We offer it at highly reasonable prices in the market.

We do the Following tests in Plastic & Polymer

- Identification of Plastic Material by DSC

- [ PP, LDPE, HDPE, Polyacetal, PET, PBT, Nylon 6, Nylon 66, Nylon 610, PVC, PS, PMMA)

- % Filler Content & Identification of Filler

- Specific Gravity

- Glass Transition(Tg)

- Heat Capacity

- Melting Peak

- Elongation at Break

- Melt Flow Index

- Flexural Strength

- Izod Impact

Comprehensive Polymer Characterization

Gain clear and thorough insights into polymer composition and properties through our state-of-the-art FTIR and DSC methods. Precise quantitative and qualitative analysis provides essential information for quality assurance, research, and material development. Our service is tailored for various plastic types and applications, ensuring accurate and actionable results.

Reliable Data with Advanced Safety

Experience both accuracy and peace of mind with features like overload protection, auto shut-off, and digital display monitoring. Our equipment operates efficiently between room temperature and 200C, meets rigorous standards for safety, and automatically calibrates to maintain consistent high performance. Enjoy seamless integration with Windows OS and digital reporting for hassle-free documentation.

FAQs of Plastic Polymer Analysis:

Q: How does FTIR Spectroscopy aid in plastic polymer identification?

A: FTIR Spectroscopy detects unique molecular vibrations in polymers, generating distinct spectral fingerprints. This enables fast, accurate identification and differentiation of plastic materials by analyzing their chemical structures.Q: What is the sample size required for analysis, and how many samples can be processed daily?

A: A minimum of 10 mg of the plastic polymer is needed for each analysis. Our system supports a sample throughput of up to 20 samples per day, ensuring efficient workflow for both small and large-scale testing.Q: When should I choose Differential Scanning Calorimetry (DSC) for polymer analysis?

A: DSC is ideal when you need detailed thermal property information, such as melting temperature, crystallinity, or glass transition. It is commonly used during polymer development, research, and quality control processes.Q: Where can I access the analytical data and reports?

A: All results are provided in digital format, compatible with Windows OS. The digital report is easily accessible, ensuring straightforward integration with your laboratory information management systems or preferred data analysis software.Q: What are the benefits of automatic and manual calibration?

A: Automatic calibration guarantees consistent and accurate results with minimal user input, while manual options allow experienced operators to fine-tune the system for specialized requirements, enhancing data reliability.Q: How does the system ensure the safety of users and samples?

A: The analysis equipment is equipped with overload protection and auto shut-off mechanisms to prevent overheating or equipment damage, supporting safe, unattended operation even during prolonged use.Q: What applications is this polymer analysis service suitable for?

A: This service excels in polymer identification, material quality assessment, and research and development projects, aiding industries in product formulation, troubleshooting, and optimization of plastic materials.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email