- Home Page

- Company Profile

-

Services

- Instrumental Analysis

- Gas Chromatography - GC

- Preparative HPLC

- Total Organic Carbon Instrumental

- TESTING LAB

- X-ray Photoelectron Spectroscopy- XPS

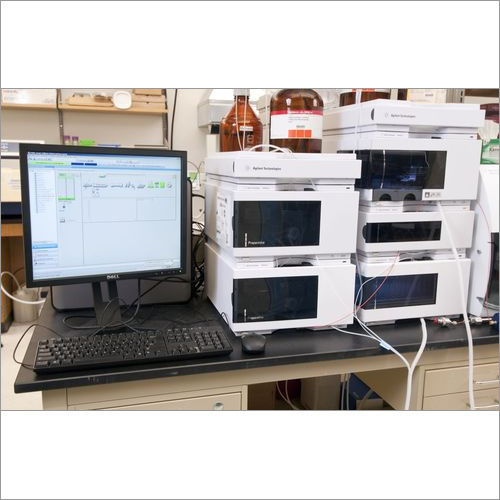

- Liquid Chromatography -HPLC

- GCMS

- Particle Size Analysis by Sedigraph

- LCMS

- Gel Permeation Chromatography - GPC

- Ion Chromatography

- Thermogravimetric Analysis - TGA

- Differential Scanning Colorimetry - DSC

- UV Visible Spectroscopy - UV-Vis

- Fourier Transform Infrared Spectroscopy - FTIR

- Inductive Couple Plasma Spectroscopy - ICP

- Atomic Absorption Spectrophotometry - AAS

- Energy Dispersive X Ray Fluorescence Spectroscopy

- Nuclear Magnetic Resonance Spectroscopy - NMR

- Colour Measurement Macbeth Spectrophotometer

- Particle Size Analysis by Malvern Mastersizer

- Scanning Electron Microscopy - SEM

- SEM-EDAX

- Transmission Electron Microscopy - TEM

- X Ray Diffraction - XRD

- Surface Area & Pore Volume Analysis by BET

- Porosity Measurement Mercury Porosimeter

- Surface Tension by Surface Tensiometer

- Elemental Analysis Using Elemental Analyzer - CHNS

- CHEMICAL TESTING LAB

- Microbiological Analysis

- Atomic Force Microscopy - AFM

- Particle Size Testing by Sympatec

- MALDI-MS

- ZETA POTENTIAL BY ZETA SIZER

- PARTICLE SIZE ANALYSIS BY NANOSIZER

- Product Analysis

- Pigment Analysis

- Perfume Flavours Fragrance Essential Oil Analysis

- Environmental - Water Analysis

- Metal & Metal Alloy Analysis

- Mineral Ores Analysis

- Plastic Polymer Analysis

- Fertilizer Soil Analysis

- Coal Analysis

- Thermic Fluid Waste Oil Analysis

- Petroleum Products Fuel Analysis

- Vegetable Oil & Fats Analysis

- Textile Analysis

- Soaps Detergent Analysis

- Food Analysis

- Electric Components Analysis

- Cementious Material & Fly Ash Analysis

- Analytical Testing Laboratories

- Speciality Chemicals Services

- Instrumental Testing

- GC Testing

- GPC Testing

- LCMS Testing

- GCMS Testing

- HPLC Testing

- Ion Chromatography Testing

- TGA Testing

- DSC Testing

- UV Testing

- FTIR Testing

- ICP Testing

- AAS Testing

- XRF Testing

- NMR Testing

- Colour Measurement Testing

- Particle Size Testing by Malvern Mastersizer

- SEM Testing

- SEM-EDAX Testing

- TEM Testing

- XRD Testing

- Surface Area & Pore Volume Testing

- Porosity Measurement Testing

- Surface Tension Testing

- CHNS Testing

- TOC Testing

- Testing Laboratory

- MICROBIOLOGICAL TESTING

- XPS Testing

- AFM Testing

- Particle Size Testing

- MALDI-MS Testing

- ZETA POTENTIAL TESTING BY ZETA SIZER

- Particle Size Testing by Nanosizer

- Particle Size Testing by Sedigraph

- Preparative HPLC Testing

- Product Testing

- Perfume-Fragrance-Essent Oil Testing Services

- Nitrosamines Impurities Testing by LCMS

- Pigment Testing Services

- Water Testing Services

- Metal Testing Services

- Ores Testing Services

- Polymer Testing Services

- Fertilizer Soil Testing Services

- Coal Testing Services

- Thermic Fluid Testing Services

- Petroleum Testing Services

- Vegetable Oil Testing Services

- Textile Testing Services

- Detergent Testing Services

- Food Testing Services

- Electric Components Testing Services

- Fly Ash Testing Services

- Chemicals Testing Services

- Solvent Testing Services

- Chemical Testing Services

- Lab Testing Services

- Laboratory Testing Services

- Instrumental Analysis

- Contact Us

X-ray Photoelectron Spectroscopy- XPS

Product Details:

- Display Integrated LCD touch screen, computer interface

- Frequency 50/60 Hz

- Driven Type Electronic/Motorized

- Material Stainless Steel (chamber), electronics-grade components

- Voltage 220 240 V, 50/60 Hz

- Measuring Range 0.1 to 6000 eV (Binding energy range)

- Usage & Applications Surface analysis, chemical composition studies, thin film analysis, material science research, semiconductor analysis

- Click to view more

X

X-ray Photoelectron Spectroscopy- XPS Price And Quantity

- 1 Unit

X-ray Photoelectron Spectroscopy- XPS Product Specifications

- Operating 15C 35C

- Standard benchtop unit (custom dimensions available)

- Stainless Steel (chamber), electronics-grade components

- Electronic/Motorized

- Approx. 250 kg

- USB, Ethernet, RS232 for data transfer and instrument control

- 220 240 V, 50/60 Hz

- 50/60 Hz

- Integrated LCD touch screen, computer interface

- 2 kW (max)

- 0.1 to 6000 eV (Binding energy range)

- Surface analysis, chemical composition studies, thin film analysis, material science research, semiconductor analysis

X-ray Photoelectron Spectroscopy- XPS Trade Information

- Cash in Advance (CID), Cheque

- 1000 Unit Per Month

- 10 Days

- Yes

- Contact us for information regarding our sample policy

- All India

- ISO 9001:2015

Product Description

X-ray Photoelectron Spectroscopy [ XPS ]Elemental composition of the surface (top 110 nm usually)

Empirical formula of pure materials

Elements that contaminate a surface

Chemical or electronic state of each element in the surface

Uniformity of elemental composition across the top surface (or line profiling or mapping)

Uniformity of elemental composition as a function of ion beam etching (or depth profiling)

Advanced Surface and Thin Film Analysis

Our XPS system delivers high-resolution analysis suitable for a variety of applications, including chemical composition studies and thin film characterization. The monochromatic Al K X-ray source ensures reliable results and reproducibility across semiconductor and materials research, enabling users to confidently interpret surface properties and elemental distributions.

Precision and Automation for Efficient Workflows

With multi-sample automation, real-time imaging, and integrated spectral fitting, this XPS instrument streamlines workflows for researchers. Its temperature-controlled sample holder and options for automation improve throughput and consistency when analyzing materials with challenging properties or during repetitive testing cycles.

Robust Safety and Versatile Data Management

Built-in interlocks and emergency power shutdown provide top-tier safety for operators, while the advanced electronics-grade construction ensures durability. Data can be exported in multiple formats, supporting detailed analysis and easy integration with laboratory data management systems.

FAQs of X-ray Photoelectron Spectroscopy- XPS:

Q: How does the XPS system achieve high energy resolution during surface analysis?

A: The XPS instrument employs a hemispherical analyzer and a monochromatic Al K X-ray source, delivering an energy resolution down to 0.5 eV. This configuration ensures precise measurements of binding energy, allowing for detailed chemical state and elemental analysis on sample surfaces.Q: What types of samples can be examined using this XPS instrument?

A: It is suitable for a broad range of samples, including metals, semiconductors, thin films, and other material science research specimens. The multi-position and temperature-controlled sample holder allows analysis under variable conditions to accommodate diverse sample requirements.Q: When is ultra-high vacuum required for XPS measurements?

A: Ultra-high vacuum (1x10 mbar) is essential during XPS analysis to prevent surface contamination and interference, ensuring accurate detection of elemental profiles and chemical states. All measurements are performed under these conditions for reliable results.Q: Where is the XPS system typically installed and operated?

A: Designed as a standard benchtop unit with custom dimensions available, the XPS system is used in research laboratories, university facilities, and industrial R&D centers, particularly within material science and semiconductor sectors. Service is available throughout India.Q: What is the process for obtaining and analyzing data from the XPS system?

A: The XPS system uses integrated software for spectral fitting and real-time imaging. Users can automate multi-sample measurements, then export data in ASCII, CSV, or proprietary formats for further analysis on computers interfaced via USB, Ethernet, or RS232.Q: How does this XPS instrument benefit material and semiconductor research?

A: It enables researchers to analyze surface composition, chemical bonding, and film thickness with high spatial and energy resolution, advancing understanding in material innovation, defect inspection, and electronic structure evaluation. Automated features increase efficiency and accuracy.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email